Strength of tapped holes: Strength tests show that any increase over 60% of thread for the tapped holes does not increase static strength of fastening. Tap breakage: If difficulty or breakage occurs, check drill size in view of material hardness and make sure tap is sharp.īreaking small drills: Small drills (1/8″ and under) break easily when they are not run at high speeds.ĭifficulty in drilling: If starting drill is difficult, thinning web of drill at the point solves this problem.Ĭlass of fit: Most commercial bolts and screws are made to fit 2A external thread standards, which fit with 2B tapped threads. Secure workpiece and drill hole using correct size tapping drill as shown on this chart.

Strength of tapped holes: Strength tests show that any increase over 60% of thread for the tapped holesĭoes not increase static strength of fastening. **For “Hard or Rough Materials”, 60-70% of thread. Recommended for “Free Cutting Materials” produces 65-75% of thread.

#DRILL TAP CHART FOR FREE#

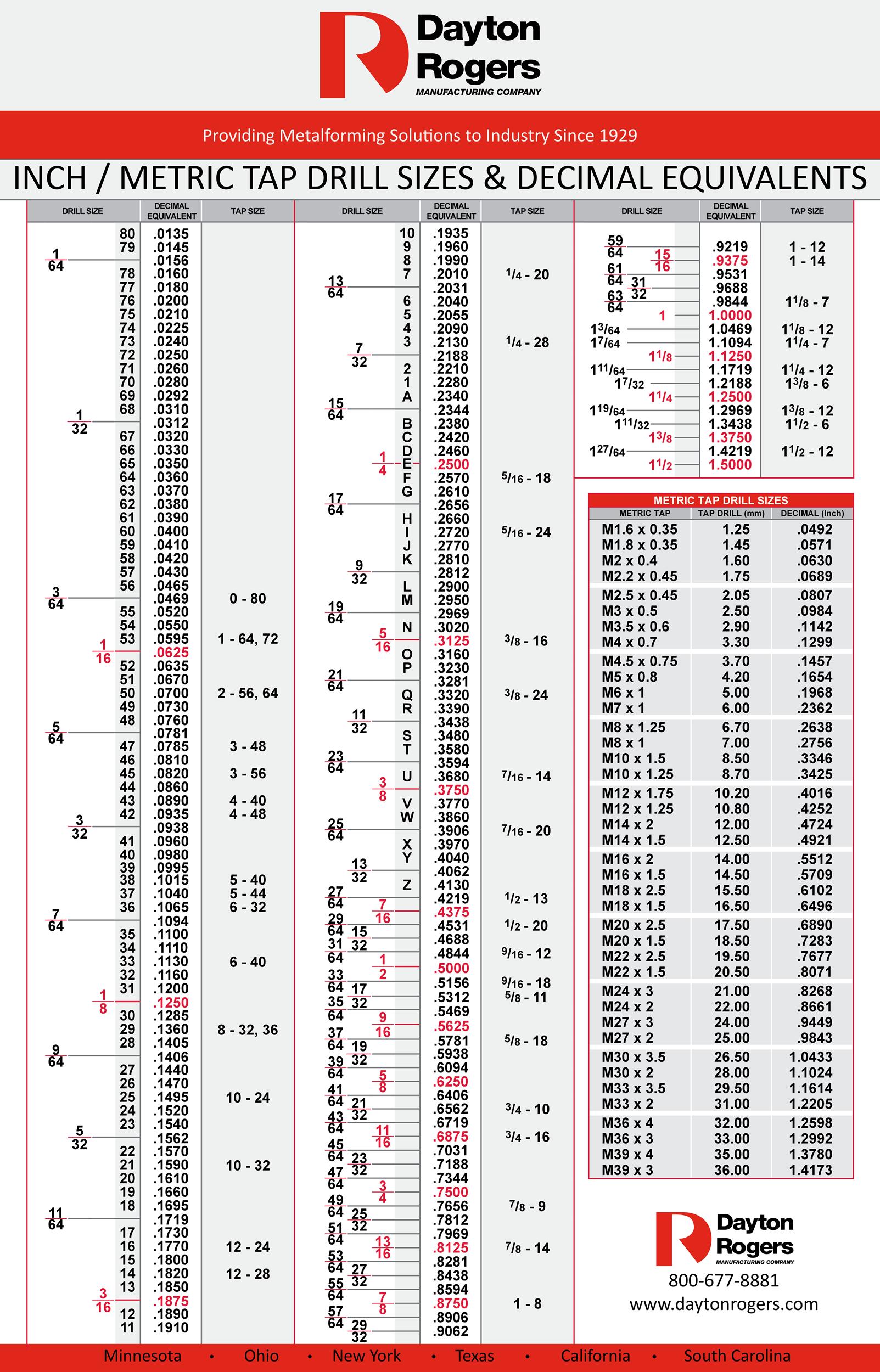

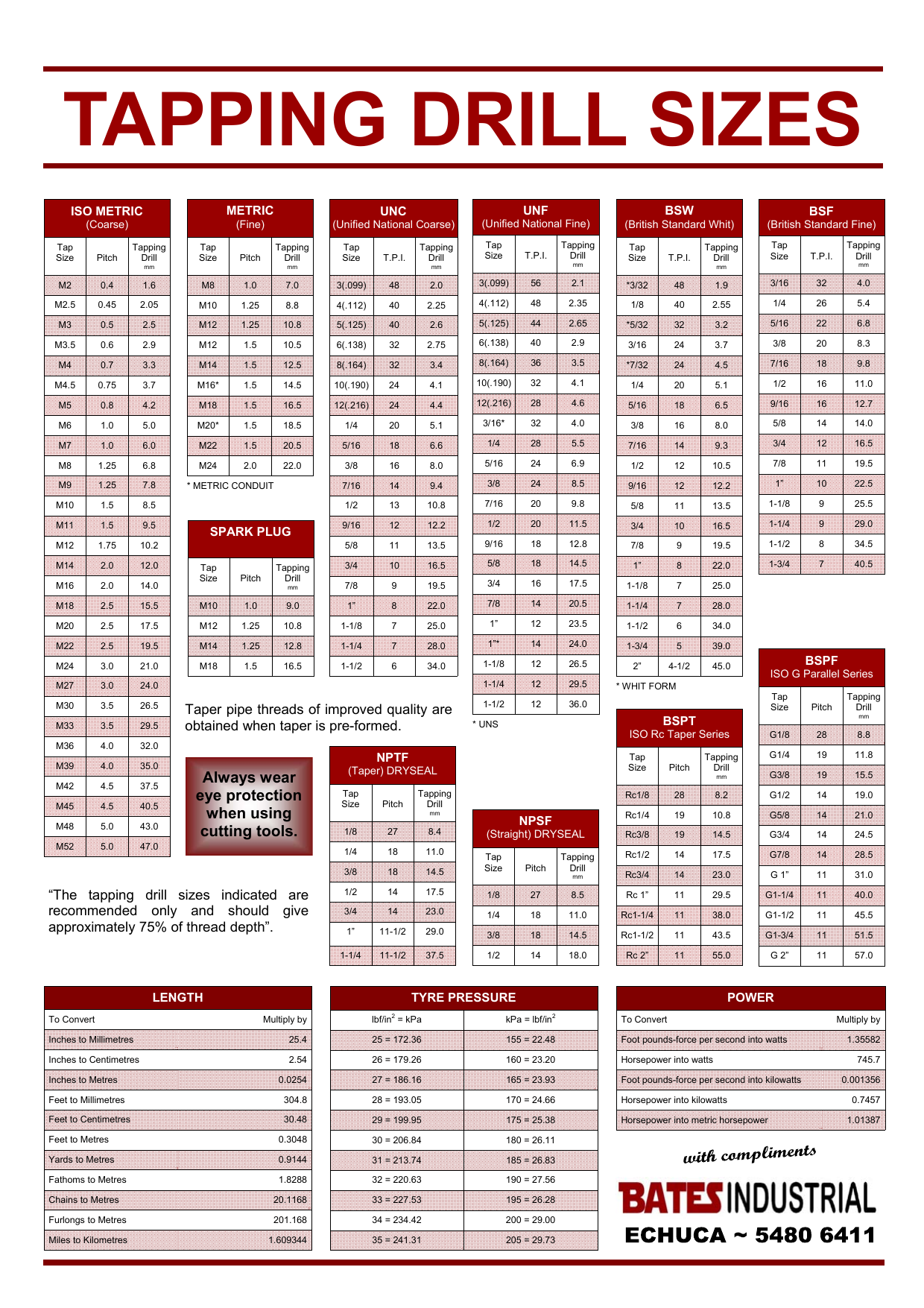

We recommend the chart for all industries looking for the right kind of information about tap drills.*DRILL SIZES FOR Free Cutting Metals Steel, Aluminum Copper and Copper Alloys Threads Per Inch: Minor Diameter 75 Thread for Aluminum, Brass & Plastics: 50 Thread for Steel, Stainless & Iron Close Fit: Free Fit 1: 0. Get details about the tap drill metric and measurement from the chart. Evaluate our metric tap drill chart to know more details about the right fit hardener for the job. For hard or tough materials, a lower percentage can really help tap life and those materials have lots of strength even at the lower percentages. For most applications, you can get longer tap tool life and a lower likelihood of breaking a tap off in the hole by using a lower percentage of thread. Metric Tap and Drill Bit Size Table 14mm x 1.5, 12.7mm, - 16mm x 2.0, 14.2mm, 35/64 16mm x 1.5, 14.7mm, - Drill sizes are for 75 depth of thread. The performance of the bit is analyzed with the geometry and sharpening of the cutting edges. The threaded percentage needs to be considered you want when you’re done tapping to know about the right drill bit size for your particular tapping application.

The size recommended in most drill bit size charts is very often not the best size to use. Metric Tap & Drill Chart METRIC THREAD SIZES Thread Size Tap Drill Size M1.6 x 0.35 1.25mm or 55 M2 x 0.4 1.60mm or 52 M2.5 x 0.45 2.05mm or 46 M3 x 0.5 2.50mm or 39 M3.5 x 0.6 2.90mm or 32 M4 x 0.7 3.30mm or 30 4.20mm or 19 M6 x 1 5.00mm or 8 M8 x 1.25 6.8mm or H M8 x 1 7.00mm or J M10 x 1.5 8.50mm or R M10 x 1.25 8.80mm or 11/32. Mounting Location : Each: Decimal Equivalents and Drill Sizes. Get the best hardware fasteners from Newport Fasteners store at a great price! Having a good metric tap drill chart is a very handy thing while buying or deciding on the right kind of fasteners for the work. Tap size: NF/NC UNF/UNC: Threads per inch: Basic major dia (inches) Basic effective dia (inches) Basic minor dia of ext. Style B charts provide a pipe tap drill chart as well as decimal equivalents of tap drill sizes, fractions, wire gauge drill sizes, letter drill sizes, and metric sizes.

0 kommentar(er)

0 kommentar(er)